In OLI’s 53-year history, each development cycle and release stage has been anchored by a consistent driving force: to support the user in mapping their real-life process as closely as possible. In pursuit of this, the Version 12 release of OLI Flowsheet: ESP process simulation software will feature a pivotal update to the Reactor Unit Block. While the previous rendition of the OLI Reactor produced a single output stream containing all phases, the updated Reactor now holds a 4-phase separation functionality (split between the Liquid-1, Liquid-2, Solid, and Vapor phases).

Key Functionalities

The new Reactor merges the fundamental functions of the standalone OLI Separator Block with those of the previous Reactor. The essential characteristics of the previous Reactor will remain available in the new Block, including the option for selecting between a Stoichiometric Conversion, Kinetic, or Gibbs reactor-type, and the flexibility in choosing between an adiabatic or isothermal equilibrium calculation. Now, however, the Block will also feature the critical functions of the OLI Separator, including 4-phase separation and comprehensive entrainment capabilities. This transforms the OLI Reactor into an object that more closely mimics its physical counterpart in a plant. Moreover, the OLI Separator remains as an available unit block to align with process steps where purely phase separation is the only required function.

DLE Case Study

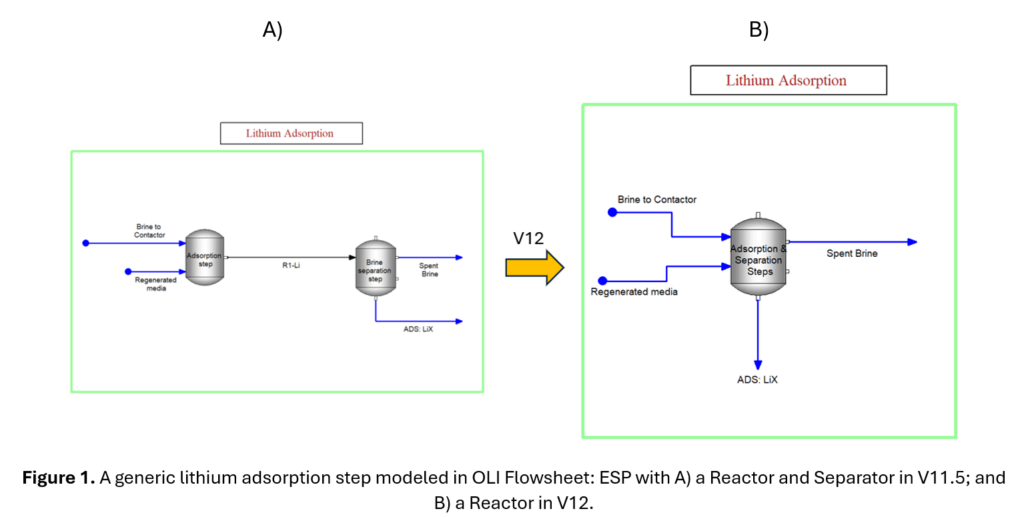

In a variety of processes, both the conversion reaction and phase separation occur in a single unit. This is often the case for Direct Lithium Extraction (DLE) applications, whereby Li(+1) ions adsorb onto a media in a reactor, generating two characteristic exit streams – the remaining brine, and the resultant Li-adsorbed media. Figure 1 illustrates how this class of reactions would be modeled in V11.5 versus V12 of OLI Flowsheet: ESP. The latter includes the following added benefits:

- The model more closely matches the physical process;

- The Flowsheet is less computationally expensive, as there are fewer blocks;

- From a user-experience perspective, the interface appears cleaner, more logical, and easier to follow.

Conclusions

These foundational updates to the Reactor Block represent a momentous stride towards accurately and intuitively modeling real-life, complex processes in OLI. For more information, please contact us.