Introduction

When companies discuss their digital transformation journey with OLI, we often ground the conversation in the motto “People, Process, Technology.” People are at the core of this transformation, driven by the sharing of information, data and other factors that allow People to make the best business decisions. Digital transformation, then, is the nexus that connects people to real-time data and operational insights that enables quick decision-making to capture windows of opportunity to unlock value for the business.

In most industrial companies, profit improvement and business innovation rely heavily on answering the following questions like these:

- How can we lower the cost of raw materials?

- How can we increase efficiency and reduce operating costs?

- How can we capture windows of opportunity?

- How can we find a more effective way to run the business?

- How can we differentiate ourselves from the competition?

- How can we identify new revenue streams to grow the business?

Static models solve today’s operational problems

A company’s engineering team (chemical plant, refinery, water treatment plant, exploration and production sites, etc.) can be divided into multiple groups. Generally, if the site is large enough, the company will separate the Chemical and Mechanical engineers for their operations and technical support areas, while electrical and civil engineers tackle infrastructure projects once the processes have been defined.

The Operations team runs the day-to-day operations of the plant, focusing on today’s plan and quotas while putting out “fires” and ensuring that the shift runs smoothly. The Technical Support team at the plant focuses on improvement projects, troubleshooting issues at the plant that may take longer than a day to resolve and develop 1, 3 and 5 years plans for the unit. Both of these teams, then, rely on a set of specialized, technical experts with years of experience in the units or assets they operate and support. These subject matter experts (SMEs) are available to answer the more difficult questions, help troubleshoot unit or asset issues and can provide support during projects.

One of the job descriptions for these SMEs is to develop and maintain simulation models of the units or assets they are responsible for, for multiple plants or sites. For example, a crude unit SME in the refining industry may have to support 5 to 10 refineries, some with multiple crude units. Then, it is easy to see that the crude unit SME for this company is maintaining anywhere from 5 to 15 (or even 20!) models. Given the limited amount of time this SME may have, getting an answer using a specialized model may take up to two weeks (sometimes more!). Therefore, it is easy to see that, for short windows of opportunity where the plant or site could squeeze more profit out of a production period, getting an answer quickly from the SME is crucial.

Capturing Windows of Opportunity

The refining industry, as well as many others, are presented with these windows of opportunity often. For example, when a hurricane heads over to Louisiana, depending on its path, refineries from the Texas’ Golden Triangle (Beaumont, Port Arthur and Orange) all the way to New Orleans may shut down to avoid catastrophic events. This allows refineries in Houston to increase production for a short period of time, one to two weeks, to take advantage of the void in fuels that the shutdown of these refineries creates upwards of 2.6 MMbbld in processed crude. Now, the Houston refineries will not be able to completely fill the void, but the reduction in fuel production (and maybe even capacity to move fuels from the area to other parts of the country) will increase fuel prices. If the Houston refineries can increase capacity by 5 to 10% for two weeks, this could account for an overall production increase of 260 kbbld. At 10 USD/bbl, the entire Houston refining area could see an increase of 18 to 36 MMUSD in additional profits for a two-week period (best case scenario). Those refineries that can quickly capture this window of opportunity will realize the biggest gains.

However, increasing production in already maxed-out plants adds complexity to the reliability and safety of the plant. Refineries are implementing digital twins, curated by SMEs, that are able to provide real-time optimization to capture these windows of opportunity. However, these digital twins are not able to see beyond yields and are blind to potential corrosion, scaling and fouling issues that production increases may bring to the units or assets.

Timely answers to reliable operating windows are needed to fully capture windows of opportunity

Unit SMEs have been using OLI’s powerful thermodynamics engine and software tools to answer questions such as: Will an increase in production increase my atmospheric tower’s overhead corrosion rates? Does this opportunity crude expose my crude unit to more corrosion? How is my desalter operations affecting fouling in my Hydroprocessing units?

These are not easy questions to answer, and specific models have to be built to answer these questions given that the answers are highly asset-specific. Even when a model exists, the speed by which operations can get an answer depends on the SME’s workload based on their support of multiple units and/or plants. Using our example above, in order to make a holistic decision that increases profitability while maintaining reliability, the SME would have to inform the plant operations team about the new Integrity Operating Window (IOW) in a timely manner. This is particularly important given that every day production can be increased by 10% which equates to an additional 26 kbpd, or 260k USD in profits (for a 260 kbpd refinery).

Refiners will not wait too long for this reliability answer and will move ahead to increase production with or without this information. However, this decision may negatively impact their units. Best case scenario, they see an increase in salt fouling that can be washed away or cleaned using online cleaning technology. Worst case scenario, the plant suffers a rate reduction for an undetermined amount of time or takes an unplanned shutdown due to increase corrosion rates creating leaks. Both scenarios will wash away any profits made during the window of opportunity.

Cloud Apps enable democratization of electrolyte thermodynamics

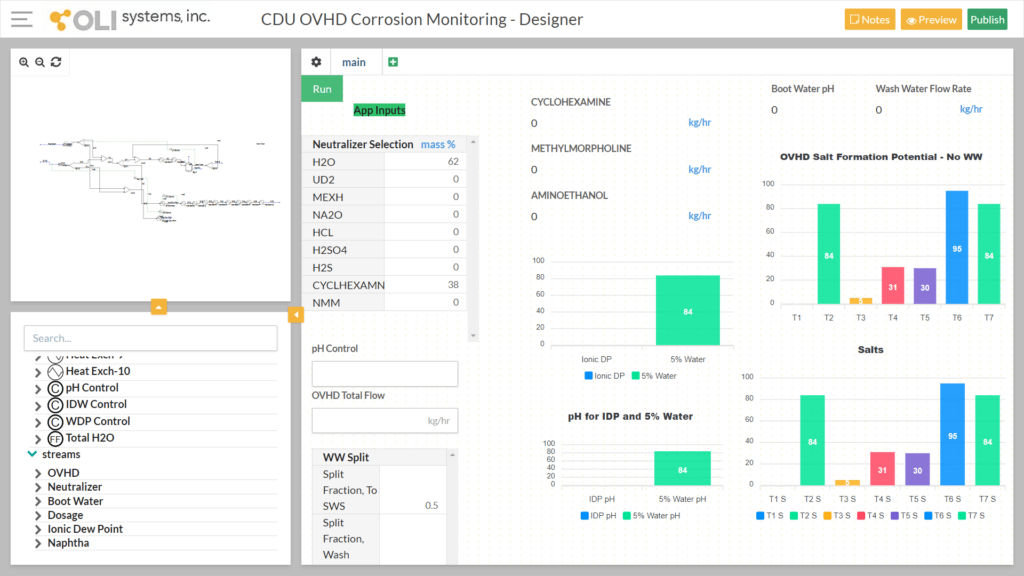

Taking into consideration these types of issues and realizing the available opportunities for plants or assets to capture windows of opportunity, OLI developed the new Cloud Apps technology platform. These Cloud Apps are, essentially, full simulation models that leverage OLI’s powerful electrolyte thermodynamic engine and can be accessed anywhere, anytime through the cloud via a web browser.

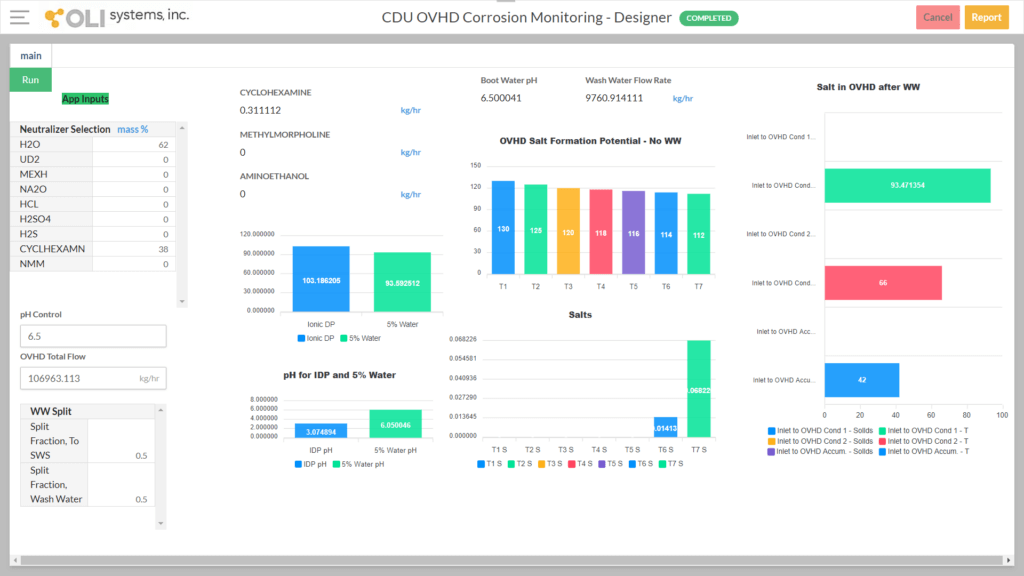

The SME will develop an App that can be deployed to the field with specific inputs and outputs. The user, then, will see a dashboard that is intuitive and easy to use with the exact information they are looking for and with familiar inputs and calculations. This information is displayed in an easy-to-consume dashboard, allowing non-experts to make operational decisions, based on very complex thermodynamics, in a matter of minutes instead of days (or even weeks!).

In addition, the same simulation model can be used to generate multiple different apps for different audiences. For example, field engineers can have an operations-oriented App that gives them the right inputs-outputs to maintain reliability and control corrosion in their units, effectively setting integrity operating windows. The field engineer can take an internet-ready device to the field and open the App via a web browser, walk the unit, call the control room to get the values/inputs for the App and advice operations based on the results they get, seconds later.

The process engineering group can have an expanded App with more functionality where they can apply the model to not only day-to-day values but also do what-if scenarios. This allows the team to develop plans and monitor the impact of rate changes to the unit, among many other things.

The business unit can have a third App where they are looking at the unit’s reliability on a general level and how it changes over time based on the business decisions and outcomes. They can use the results to track how business decisions affected the unit’s corrosion exposure and fouling to then correlate it to the unit’s on-stream factor. Now the business can build intelligence on how the units can be pushed reliably, and more importantly, safely.

These three different Apps are all based on the same model, curated by the same SME who now becomes the App Custodian. The SME can give access to any groups or persons to the Apps they create. In addition, this type of App deployment allows for collaboration between all three groups. Working with the SME, each group can provide feedback on what works for them, what should be removed or is not as useful, and what additional inputs and outputs they would like to have available.

Expert results, now

OLI’s new Cloud Apps provide rapid, decision-making tools businesses need to deliver impactful business outcomes such as increasing profitability, asset reliability, sustainability and operations efficiency while mitigating operations risks and reducing costs. SMEs can develop these expert-level tools with intuitive controls that can be accessed anywhere, anytime, can be deployed without the need to download and install software, maintain a license file or worry about the IT infrastructure. App users can have access to expert-level, electrolyte thermodynamic solutions in a matter of minutes and use the results to drive operations, troubleshoot units and enhance reliability and safety.

What tools comprise OLI’s Cloud Apps?

The OLI Cloud Apps consist of OLI’s thermodynamic framework and modeling capabilities available through OLI Flowsheet: ESP and access to OLI’s App Builder to upload the flowsheet files and develop the Apps. These will be available in June 2021 as part of the OLI Platform V11 release.

OLI has worked with clients in the past to generate models and train engineers to run them to extract the same information, providing valuable insights to plants and business who are just starting in this journey. OLI can provide training, support and consulting services for businesses who would like to develop their own Cloud Apps.

Contact OLI for more information or to schedule a meeting with an OLI expert to see how we can assist you.